Call our experienced team today

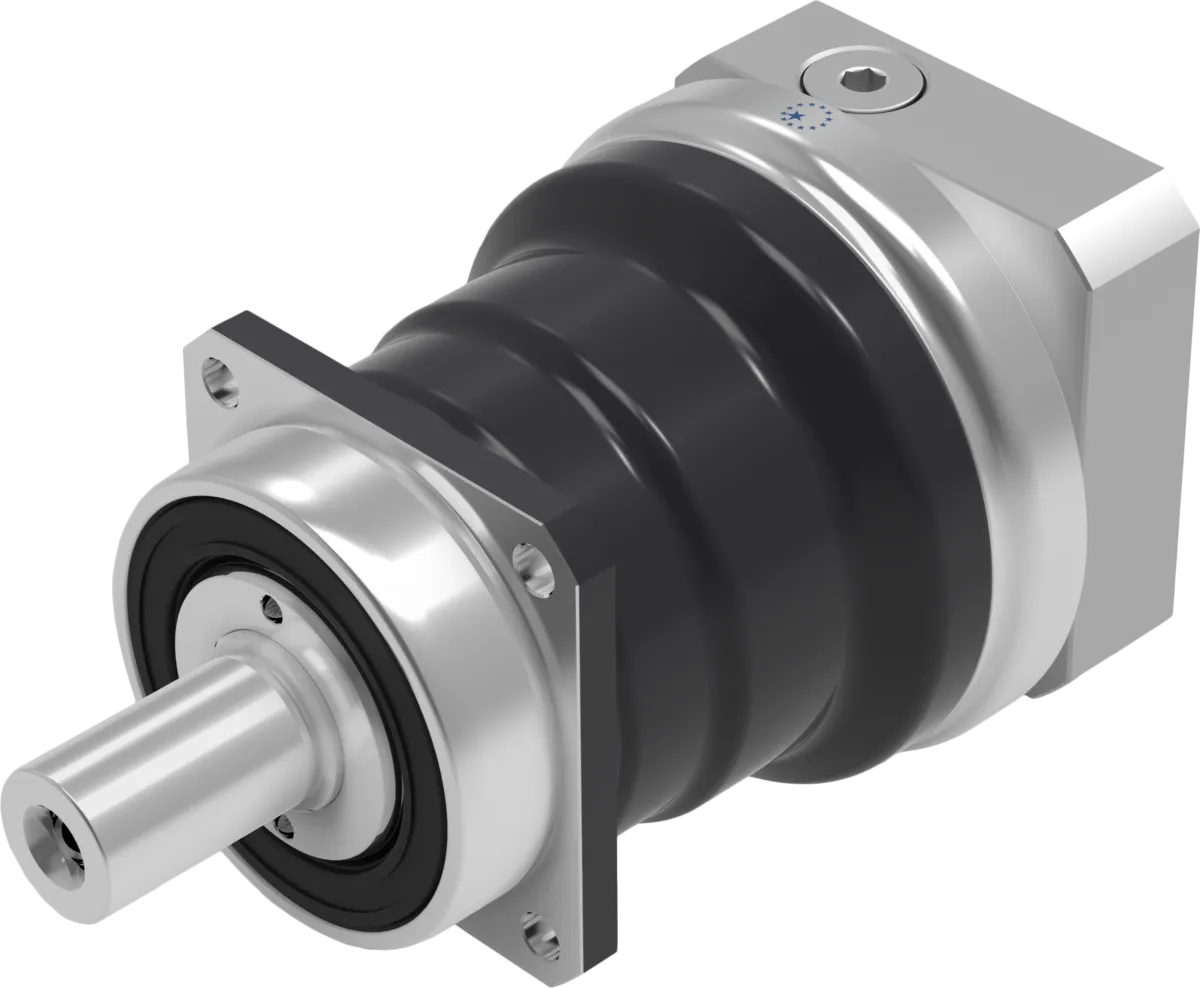

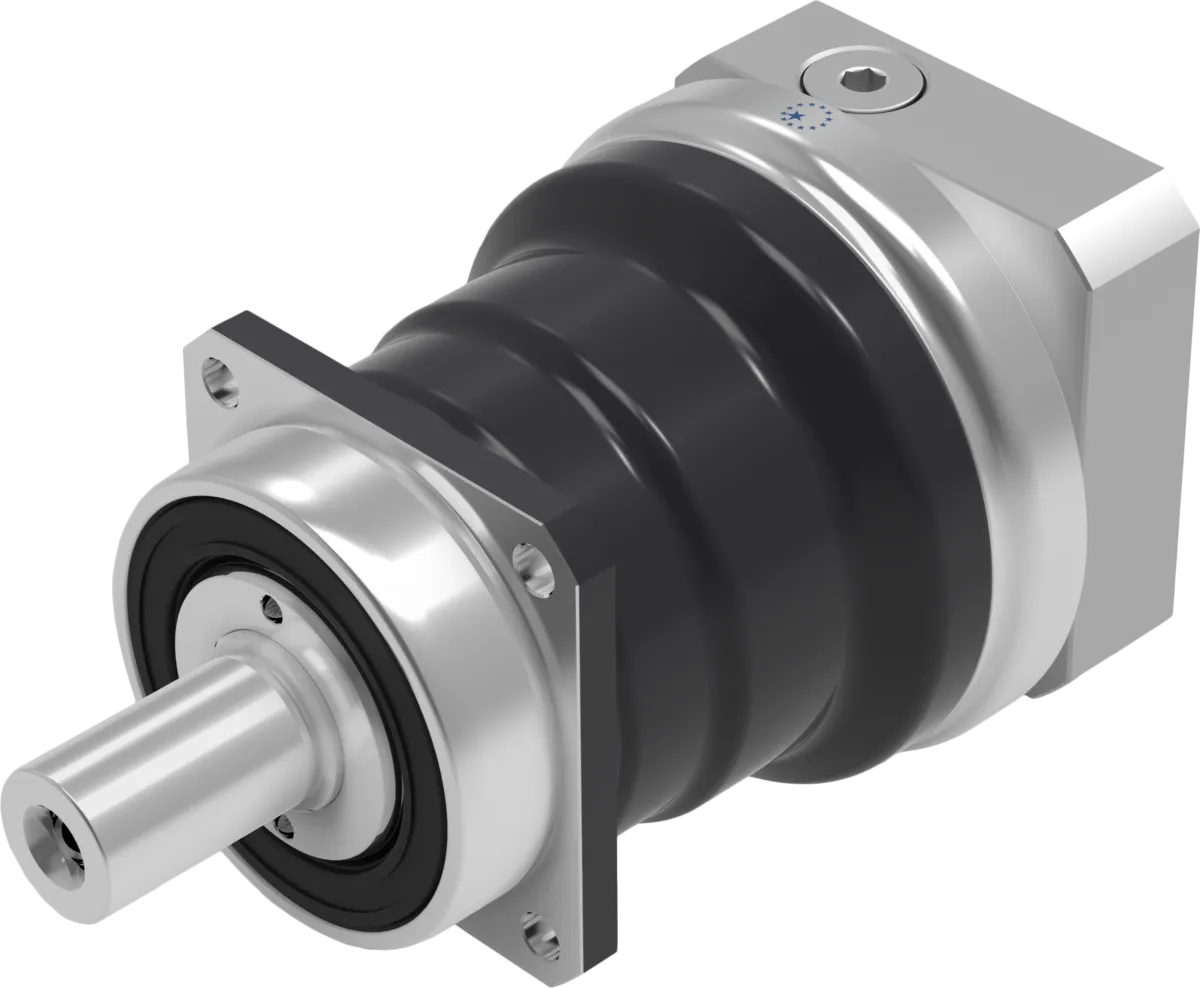

Unleash Precision & Power with Apex Dynamics' Planetary Gearboxes

Delivering unmatched precision, reliability, and power for modern industrial applications.

Or call 0121 661 3642 to speak with an expert.

Trusted by Industry Leaders in Automation, Packaging, and Beyond

Over 10,000 units delivered worldwide - 2–3 week standard lead time - 5-year warranty

Unleash Precision & Power with Apex Dynamics' Planetary Gearboxes

Delivering unmatched precision, reliability, and power for modern industrial applications.

Or call 0121 661 3642 to speak with an expert.

Trusted by Industry Leaders in Automation, Packaging, and Beyond

Over 10,000 units delivered worldwide - 2–3 week standard lead time - 5-year warranty

Why Settle for Outdated or Inefficient Gearboxes?

We understand that every hour of downtime is a blow to your productivity. If these headaches sound familiar, it’s time for a change.

Frequent Failures - Nothing stalls progress quite like equipment breakdowns. Whether it’s compromised components or excessive wear, frequent failures keep you pouring resources into emergency repairs instead of boosting output.

Excessive Backlash & Inaccuracy - When your gearbox can’t maintain precision, it impacts your entire process. Inaccurate movements lead to flawed products, wasted materials, and frustrated teams trying to course-correct on the fly.

Bulky, Obsolete Designs - Space is valuable, and an outdated or oversized gearbox can cramp your operations—literally. Legacy designs can restrict machine layouts and complicate future expansions or upgrades.

Long Lead Times & Missed Deadlines - A delayed gearbox delivery means your project or production line slips behind schedule, inviting additional costs and lost opportunities. Waiting around for the right part can grind progress to a halt.

At Apex Dynamics, we’ve engineered our planetary gearboxes to address these issues head-on—so you can finally bypass the setbacks and focus on what you do best: driving your business forward.

The Apex Dynamics Advantage: Why Our Planetary Gearboxes Excel

At Apex Dynamics, we’ve dedicated years of engineering expertise towards creating planetary gearboxes that address real-world industrial challenges head-on. Here’s how we deliver tangible value where it matters most:

Precision Engineering

Every Apex Dynamics planetary gearbox is designed to minimise backlash and maximise control. Whether your application involves robotics, high-speed packaging lines, or complex automation, our gearboxes ensure repeatable accuracy and consistent output.

Compact Yet Powerful

Don’t let a tight space compromise your performance. Our gearboxes boast industry-leading torque density, giving you the power you need without the bulk—making them ideal for both new equipment designs and retrofits.

Unmatched Reliability

Nobody has time for unnecessary downtime. With robust components, stringent quality control, and a 5-year warranty as standard, our gearboxes deliver the dependable performance you need to keep your production floor humming.

Customisation

We understand that each project has unique parameters. From bespoke gear ratios to specialised materials and mounting options, our custom solutions cater to diverse requirements, ensuring you always get the ideal fit for your operational needs.

Swift Lead Times

Delayed components lead to missed deadlines. Our streamlined manufacturing process enables standard lead times of around 2–3 weeks, so you can get up and running—or growing—without losing valuable momentum.

Ready to Transform Your Workflow?

Take the first step towards more efficient, profitable operations.

Or call 0121 661 3642 to speak with an expert.

Discover Our Servo Gearboxes

GL-Series High Precision Planetary Gearboxes

AFH-Series High Precision Planetary Gearboxes

AFHK-Series High Precision Planetary Gearboxes

APCK-Series High Precision Planetary Gearboxes

Take the first step towards unmatched performance and precision. Ask an expert today and discover how Apex Dynamics can transform your business.

Why Settle for Outdated or Inefficient Gearboxes?

We understand that every hour of downtime is a blow to your productivity. If these headaches sound familiar, it’s time for a change.

Frequent Failures - Nothing stalls progress quite like equipment breakdowns. Whether it’s compromised components or excessive wear, frequent failures keep you pouring resources into emergency repairs instead of boosting output.

Excessive Backlash & Inaccuracy -

When your gearbox can’t maintain precision, it impacts your entire process. Inaccurate movements lead to flawed products, wasted materials, and frustrated teams trying to course-correct on the fly.

Bulky, Obsolete Designs -

Space is valuable, and an outdated or oversized gearbox can cramp your operations—literally. Legacy designs can restrict machine layouts and complicate future expansions or upgrades.

Long Lead Times & Missed Deadlines -

A delayed gearbox delivery means your project or production line slips behind schedule, inviting additional costs and lost opportunities. Waiting around for the right part can grind progress to a halt.

At Apex Dynamics, we’ve engineered our planetary gearboxes to address these issues head-on—so you can finally bypass the setbacks and focus on what you do best: driving your business forward.

The Apex Dynamics Advantage: Why Our Planetary Gearboxes Excel

At Apex Dynamics, we’ve dedicated years of engineering expertise towards creating planetary gearboxes that address real-world industrial challenges head-on. Here’s how we deliver tangible value where it matters most:

Precision Engineering

Every Apex Dynamics planetary gearbox is designed to minimise backlash and maximise control. Whether your application involves robotics, high-speed packaging lines, or complex automation, our gearboxes ensure repeatable accuracy and consistent output.

Compact Yet Powerful

Don’t let a tight space compromise your performance. Our gearboxes boast industry-leading torque density, giving you the power you need without the bulk—making them ideal for both new equipment designs and retrofits.

Unmatched Reliability

Nobody has time for unnecessary downtime. With robust components, stringent quality control, and a 5-year warranty as standard, our gearboxes deliver the dependable performance you need to keep your production floor humming.

Customisation

We understand that each project has unique parameters. From bespoke gear ratios to specialised materials and mounting options, our custom solutions cater to diverse requirements, ensuring you always get the ideal fit for your operational needs.

Swift Lead Times

Delayed components lead to missed deadlines. Our streamlined manufacturing process enables standard lead times of around 2–3 weeks, so you can get up and running—or growing—without losing valuable momentum.

Ready to Transform Your Workflow?

Take the first step towards more efficient, profitable operations.

Or call 0121 661 3642 to speak with an expert.

Discover Our

Servo Gearboxes

GL-Series High Precision Planetary Gearboxes

AFH-Series High Precision Planetary Gearboxes

AFHK-Series High Precision Planetary Gearboxes

APCK-Series High Precision Planetary Gearboxes

Take the first step towards unmatched performance and precision. Ask an expert today and discover how Apex Dynamics can transform your business.

Why Choose Apex Dynamics?

Our servo gearboxes come with a range of unbeatable features and benefits, setting us apart from the competition

Patented

Designs

Experience unmatched innovation and efficiency, thanks to our ground breaking patented designs.

5-Year

Warranty

Gain peace of mind with our industry-leading 5-year warranty, ensuring durability and reliability

Lightning-Fast

Lead Time

Get your projects up and running swiftly with our impressive 2-3 week lead time.

Guaranteed

Delivery

Say goodbye to production delays and uncertainties with our commitment to on-time delivery.

Atex as

Standard

Trust in our products that meet Atex standards, prioritising safety and compliance.

Take the first step towards unmatched performance and precision. Call us today and discover how Apex Dynamics can transform your business.

Your success is just one call away. Don't wait, elevate!

Take the first step towards unmatched performance and precision. Call us today and discover how Apex Dynamics can transform your business. Your success is just one call away. Don't wait, elevate!

Case Study

CA Group Chooses Apex Gearboxes

Case Study

CA Group Chooses Apex Gearboxes

Don't Just Take Our Word For It

We really appreciate the support provided by the knowledgeable expert team at Apex Dynamics.

Having identified the problem, this was a truly collaborative project that resulted in the right solution to provide the flexibility needed and ensure our converting machine runs smoothly.

- Stuart Lowe,

CA Group Works Engineering Manager

The fast delivery times are really important to us. We have 6, 8, 10 months to turn a machine around, so we can’t wait long for the delivery of a gearbox. Apex have it well under control.

We were really pleased with the levels of service for this project, as we got good products, at a good price, with good customer support and good delivery

- Phillip Denison, Senior Mechanical Designer at Electron Engineering Services

We have been using Apex Dynamics products for some time in our machines and have been very pleased with the relationship we have built with them.

When we looked for the correct gearboxes for our high precision applications, we found Apex Dynamics products very reliable and able to meet our high standards for speed, accuracy and precision at the interface between motor and machine.

- Daniel Fitton, PTG Holroyd Customer Support Manager

Don't Just Take Our Word For It

We really appreciate the support provided by the knowledgeable expert team at Apex Dynamics.

Having identified the problem, this was a truly collaborative project that resulted in the right solution to provide the flexibility needed and ensure our converting machine runs smoothly.

- Stuart Lowe,

CA Group Works Engineering Manager

The fast delivery times are really important to us. We have 6, 8, 10 months to turn a machine around, so we can’t wait long for the delivery of a gearbox. Apex have it well under control.

We were really pleased with the levels of service for this project, as we got good products, at a good price, with good customer support and good delivery

- Phillip Denison, Senior Mechanical Designer at Electron Engineering Services

We have been using Apex Dynamics products for some time in our machines and have been very pleased with the relationship we have built with them.

When we looked for the correct gearboxes for our high precision applications, we found Apex Dynamics products very reliable and able to meet our high standards for speed, accuracy and precision at the interface between motor and machine.

- Daniel Fitton, PTG Holroyd Customer Support Manager

Take the first step towards unmatched performance and precision. Call us today and discover how Apex Dynamics can transform your business.

Your success is just one call away. Don't wait, elevate!

Take the first step towards unmatched performance and precision. Call us today and discover how Apex Dynamics can transform your business. Your success is just one call away. Don't wait, elevate!

Frequently Asked Questions

What is a planetary gearbox, and why is it used in industrial automation?

A planetary gearbox is a type of gear system that consists of a central sun gear, multiple planet gears, and an outer ring gear. It is commonly used in industrial automation because of its compact size, high torque output, and excellent efficiency. These characteristics make it ideal for applications where space is limited, and precise speed reduction or torque multiplication is required.

What are the key advantages of using planetary gearboxes in automation systems?

The main advantages of using planetary gearboxes in industrial automation include high torque density, excellent efficiency (typically 90-95%), low backlash, and the ability to handle shock loads. They are also known for their durability, reliability, and versatility, making them suitable for a wide range of applications.

How do I choose the right planetary gearbox for my automation project?

Selecting the right planetary gearbox involves considering factors such as the required torque output, input and output speed ratios, available space, backlash tolerance, and environmental conditions. It's essential to consult with a gearbox manufacturer or engineer to ensure you choose a gearbox that meets your specific application requirements.

Can planetary gearboxes be customised for specific automation projects?

Yes, many gearbox manufacturers offer customisation options to tailor planetary gearboxes to the unique needs of your automation project. Customisations can include gear ratios, materials, lubrication options, mounting configurations, and special coatings for harsh environments. Discuss your requirements with the manufacturer to determine the best configuration.

What maintenance is required for planetary gearboxes in industrial automation applications?

Planetary gearboxes typically require minimal maintenance if properly lubricated and installed. Regularly checking and replenishing lubricants, monitoring for abnormal noise or vibration, and conducting visual inspections are essential maintenance tasks. Maintenance intervals may vary depending on usage, but most industrial planetary gearboxes have long service lives when maintained correctly.

Privacy Policy | Terms and Conditions

Copyright © 2023 Apex Dynamics Ltd. All Rights Reserved | Website designed by Trifle

Frequently Asked Questions

What is a planetary gearbox, and why is it used in industrial automation?

A planetary gearbox is a type of gear system that consists of a central sun gear, multiple planet gears, and an outer ring gear. It is commonly used in industrial automation because of its compact size, high torque output, and excellent efficiency. These characteristics make it ideal for applications where space is limited, and precise speed reduction or torque multiplication is required.

What are the key advantages of using planetary gearboxes in automation systems?

The main advantages of using planetary gearboxes in industrial automation include high torque density, excellent efficiency (typically 90-95%), low backlash, and the ability to handle shock loads. They are also known for their durability, reliability, and versatility, making them suitable for a wide range of applications.

How do I choose the right planetary gearbox for my automation project?

Selecting the right planetary gearbox involves considering factors such as the required torque output, input and output speed ratios, available space, backlash tolerance, and environmental conditions. It's essential to consult with a gearbox manufacturer or engineer to ensure you choose a gearbox that meets your specific application requirements.

Can planetary gearboxes be customised for specific automation projects?

Yes, many gearbox manufacturers offer customisation options to tailor planetary gearboxes to the unique needs of your automation project. Customisations can include gear ratios, materials, lubrication options, mounting configurations, and special coatings for harsh environments. Discuss your requirements with the manufacturer to determine the best configuration.

What maintenance is required for planetary gearboxes in industrial automation applications?

Planetary gearboxes typically require minimal maintenance if properly lubricated and installed. Regularly checking and replenishing lubricants, monitoring for abnormal noise or vibration, and conducting visual inspections are essential maintenance tasks. Maintenance intervals may vary depending on usage, but most industrial planetary gearboxes have long service lives when maintained correctly.

Privacy Policy | Terms and Conditions

Copyright © 2023 Apex Dynamics Ltd. All Rights Reserved | Website designed by Trifle